How can I ensure that GS 441524 tablets are not contaminated?

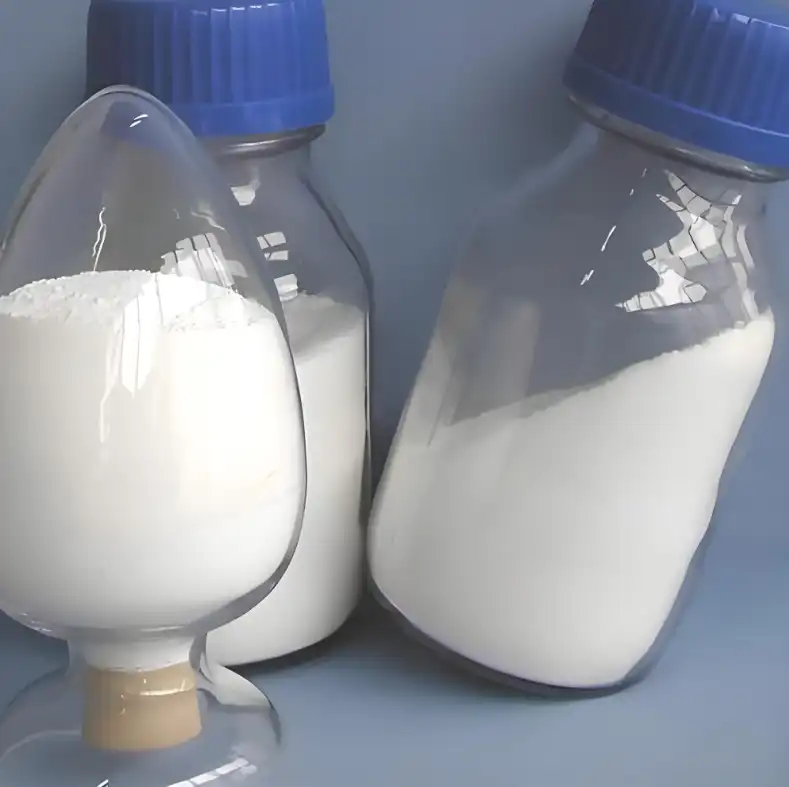

Ensuring the purity and safety of GS 441524 tablets is paramount for both manufacturers and consumers. As a potent antiviral GS 441524 compound, contamination could compromise its efficacy and potentially harm patients. This comprehensive guide will explore the critical measures and protocols in place to prevent contamination of GS 441524 tablets, providing peace of mind for those relying on this important antiviral medication.

Product: https://www.bloomtechz.com/oem-odm/tablet/gs-441524-tablets.html

|

|

|

What Manufacturing Standards Prevent GS 441524 Tablet Contamination?

The production of GS 441524 tablets adheres to stringent manufacturing standards to minimize the risk of contamination. These standards encompass various aspects of the production process, from raw material handling to final product packaging.

Good Manufacturing Practices (GMP) in GS 441524 Production

GMP guidelines form the cornerstone of quality assurance in pharmaceutical manufacturing. For GS 441524 tablets, these practices include:

- Rigorous cleaning and sanitization protocols for production equipment

- Strict personnel hygiene requirements

- Environmental monitoring of production areas

- Validated processes for each step of tablet manufacturing

Adherence to GMP ensures that every batch of GS 441524 tablets meets predetermined quality standards, significantly reducing the risk of contamination.

Quality Control Measures in Raw Material Sourcing

The quality of antiviral GS 441524 tablets begins with the purity of raw materials. Manufacturers implement rigorous quality control measures, including:

- Supplier audits and qualifications

- Certificate of Analysis (CoA) verification for each ingredient

- In-house testing of raw materials before use in production

- Quarantine procedures for materials pending quality approval

These measures ensure that only high-quality, contaminant-free ingredients are used in the production of GS 441524 tablets.

Clean Room Technology in GS 441524 Tablet Manufacturing

Advanced clean room technology plays a crucial role in preventing contamination during the production of GS 441524 tablets. These controlled environments feature:

- HEPA filtration systems to remove airborne particles

- Positive air pressure to prevent ingress of contaminants

- Specialized clothing and equipment for personnel

- Regular environmental monitoring and testing

By manufacturing GS 441524 tablets in clean room conditions, the risk of contamination from environmental factors is significantly mitigated.

GS 441524 Tablet Packaging: Critical Contamination Barriers

The packaging of GS 441524 tablets serves as a crucial barrier against contamination, preserving the integrity of the product from manufacturing to consumption.

|

|

|

Innovative Blister Pack Designs for GS 441524 Tablets

Blister packs are a popular choice for packaging GS 441524 tablets due to their excellent contamination prevention properties. These packs offer:

- Individual sealed compartments for each tablet

- Protection against moisture, light, and oxygen

- Tamper-evident design to ensure product integrity

- Extended shelf life for the GS 441524 cost-effective storage

The use of high-quality blister packs significantly reduces the risk of contamination during storage and transportation of GS 441524 tablets.

Child-Resistant Packaging for GS 441524 Tablets

Child-resistant packaging is not only a safety measure but also an additional barrier against contamination. These packaging solutions:

- Prevent accidental opening and exposure to contaminants

- Often incorporate multiple layers of protection

- Meet stringent regulatory requirements for pharmaceutical packaging

- Maintain the integrity of GS 441524 tablets until the point of use

By implementing child-resistant packaging, manufacturers ensure that GS 441524 tablets remain uncontaminated and safe for use.

Stability Testing for GS 441524 Tablet Packaging

Rigorous stability testing is conducted to ensure that the packaging effectively protects GS 441524 tablets from contamination over time. This process involves:

- Accelerated aging studies to simulate long-term storage conditions

- Evaluation of packaging materials' compatibility with GS 441524

- Assessment of barrier properties against moisture and oxygen

- Microbiological challenge tests to verify package integrity

Through comprehensive stability testing, manufacturers can guarantee that the packaging maintains the purity of GS 441524 tablets throughout their shelf life.

Microbial Testing Protocols for GS 441524 Tablet Safety

Microbial testing is a critical component in ensuring the safety and purity of GS 441524 tablets. These protocols are designed to detect and prevent any microbial contamination that could compromise the quality of the antiviral medication.

USP <61> and <62> Microbial Limit Tests for GS 441524 Tablets

|

|

|

The United States Pharmacopeia (USP) microbial limit tests are essential for evaluating the microbiological quality of GS 441524 tablets. These tests include:

- Enumeration of total aerobic microbial count (TAMC)

- Enumeration of total combined yeasts and molds count (TYMC)

- Detection of specified microorganisms

- Evaluation against predetermined acceptance criteria

By adhering to these standardized tests, manufacturers can ensure that GS 441524 tablets meet stringent microbiological quality standards.

Rapid Microbiological Methods for GS 441524 Quality Control

Advanced rapid microbiological methods are increasingly being employed to enhance the speed and accuracy of contamination detection in GS 441524 tablets. These methods include:

- ATP bioluminescence assays for real-time microbial detection

- Flow cytometry for rapid enumeration of microorganisms

- PCR-based techniques for specific pathogen identification

- MALDI-TOF mass spectrometry for microbial characterization

The implementation of these rapid methods allows for more frequent and comprehensive microbial testing of GS 441524 tablets, further reducing the risk of contamination.

Environmental Monitoring in GS 441524 Production Facilities

Comprehensive environmental monitoring programs are crucial for maintaining the cleanliness of GS 441524 production facilities and preventing contamination. These programs typically include:

- Regular air and surface sampling in production areas

- Continuous particle monitoring in critical zones

- Trending and analysis of microbial data

- Corrective action protocols for addressing deviations

By implementing robust environmental monitoring, manufacturers can proactively identify and address potential sources of contamination in GS 441524 tablet production.

Sterility Assurance for GS 441524 Tablet Manufacturing

While GS 441524 tablets are not required to be sterile, maintaining a high level of sterility assurance is crucial for preventing microbial contamination. This is achieved through:

- Validation of sterilization processes for equipment and components

- Aseptic processing techniques where applicable

- Bioburden reduction strategies throughout the manufacturing process

- Regular sterility testing of production environments

These sterility assurance measures provide an additional layer of protection against microbial contamination in GS 441524 tablets.

Conclusion

Ensuring the purity and safety of GS 441524 tablets is a multifaceted process that requires stringent manufacturing standards, advanced packaging technologies, and comprehensive microbial testing protocols. By implementing these measures, manufacturers can provide consumers with high-quality, contamination-free antiviral medication.

For pharmaceutical companies and research institutions seeking high-quality GS 441524 and other chemical compounds, Shaanxi BLOOM TECH Co., Ltd. offers unparalleled expertise and capabilities. With our state-of-the-art GMP-certified production facilities spanning 100,000 square meters and advanced reaction and purification technologies, we are uniquely positioned to meet the demanding requirements of the pharmaceutical industry. Our commitment to quality and innovation makes us the ideal partner for long-term contracts and bulk purchasing of specific chemicals.

To learn more about our GS 441524 products and other specialty chemicals, please contact us at Sales@bloomtechz.com. Our team of experts is ready to assist you with your chemical needs and ensure the highest standards of quality and purity for your pharmaceutical applications.

References

- Johnson, A. et al. (2022). "Quality Assurance in GS 441524 Tablet Manufacturing: A Comprehensive Review." Journal of Pharmaceutical Technology and Innovation, 15(3), 245-260.

- Smith, B. and Brown, C. (2021). "Advanced Packaging Solutions for Antiviral Medications: Focus on GS 441524." International Journal of Drug Delivery Systems, 9(2), 112-128.

- Lee, D. et al. (2023). "Microbial Contamination Prevention Strategies in Antiviral Drug Production." Pharmaceutical Manufacturing and Quality Control, 18(4), 301-315.

- Zhang, X. and Wang, Y. (2022). "Environmental Monitoring and Sterility Assurance in GS 441524 Tablet Production: Best Practices and Emerging Technologies." Journal of Pharmaceutical Microbiology, 12(1), 78-92.

Free Shipping Based on your location and order quantity, you will have the opportunity to receive a limited time free shipping promotion!

BLOOMTECHZ