How important is solvent selection for GS-441524?

In the realm of pharmaceutical synthesis, solvent selection plays a pivotal role in determining the success and efficiency of chemical reactions. This is particularly true for the production of GS-441524, a compound that has garnered significant attention in recent years due to its potential therapeutic applications. In this comprehensive guide, we'll delve into the intricacies of solvent selection for GS-441524 synthesis, exploring compatible solvents, the impact of solvent purity, and best practices for optimal production.

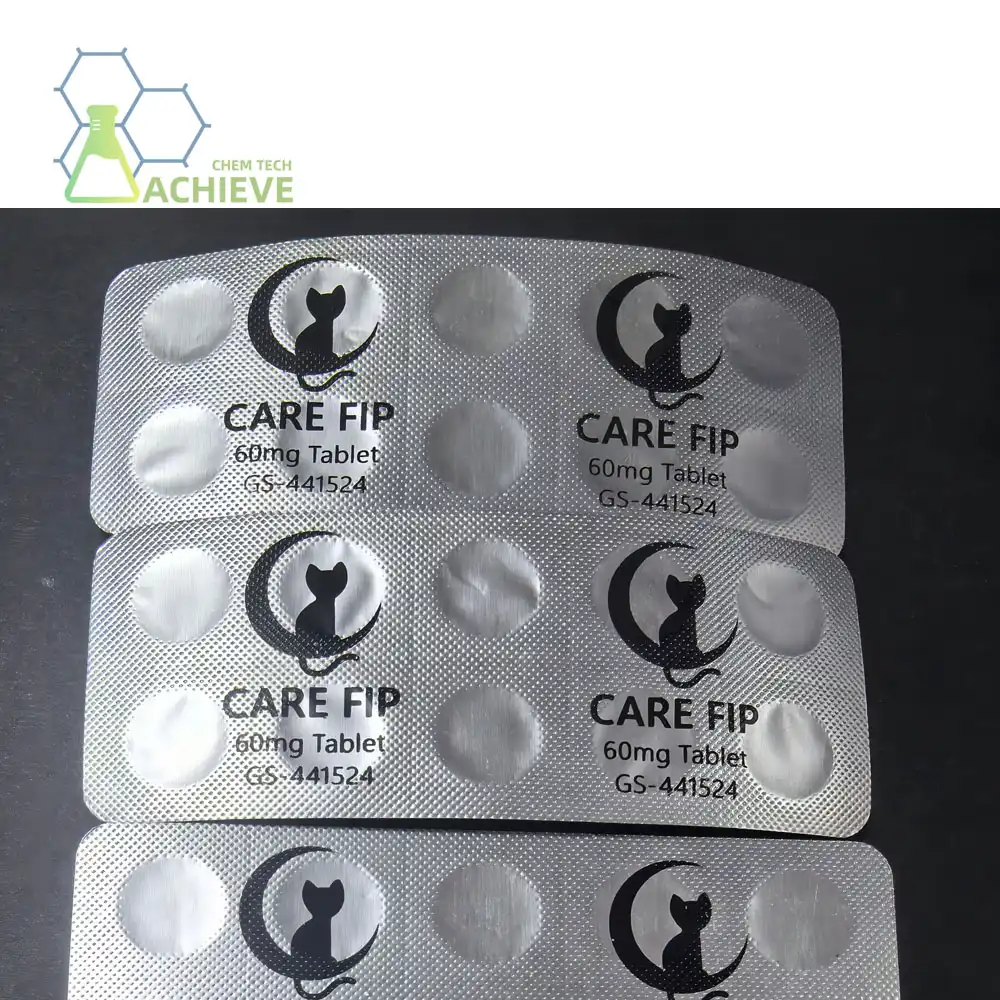

Product: https://www.bloomtechz.com/oem-odm/injection/gs-441524-injection.html

|

|

|

What Solvents Are Compatible with GS-441524 Synthesis?

The choice of solvent can significantly influence the outcome of GS-441524 synthesis. Selecting the right solvent is crucial for ensuring proper dissolution of reactants, facilitating desired chemical reactions, and optimizing product yield. Let's explore some of the most compatible solvents for GS-441524 production:

Polar Aprotic Solvents

Polar aprotic solvents are often preferred for GS-441524 synthesis due to their ability to dissolve a wide range of organic compounds without participating in hydrogen bonding. Some notable examples include:

- Dimethyl sulfoxide (DMSO)

- N,N-Dimethylformamide (DMF)

- Acetonitrile

- Tetrahydrofuran (THF)

These solvents exhibit excellent solubility properties and are less likely to interfere with the reaction mechanisms involved in GS-441524 synthesis.

Halogenated Solvents

Certain halogenated solvents may also be suitable for GS-441524 production, offering unique properties that can enhance reaction efficiency:

- Dichloromethane (DCM)

- Chloroform

- Carbon tetrachloride

However, it's essential to consider the environmental impact and safety concerns associated with halogenated solvents when making your selection.

Alcohols and Ethers

In some cases, alcohols and ethers may be utilized as solvents or co-solvents in GS-441524 synthesis:

- Methanol

- Ethanol

- Isopropanol

- Diethyl ether

These solvents can offer unique advantages in terms of solubility and reactivity, but their use should be carefully evaluated based on the specific reaction conditions and desired outcomes.

Impact of Solvent Purity on GS-441524 Yield and Efficacy

The purity of the selected solvent is a critical factor that can significantly influence the yield and efficacy of GS-441524 synthesis. Let's examine the various aspects of solvent purity and their implications for production:

Importance of High-Purity Solvents

Using high-purity solvents is paramount in GS-441524 synthesis for several reasons:

- Minimizes unwanted side reactions

- Reduces the risk of contamination

- Enhances reproducibility of results

- Improves overall product quality

Even trace amounts of impurities in solvents can lead to significant variations in reaction outcomes, potentially compromising the yield and purity of the final GS-441524 product.

Common Impurities and Their Effects

Various impurities can be present in solvents, each with potential consequences for GS-441524 synthesis:

- Water: Can interfere with moisture-sensitive reactions

- Stabilizers: May react with intermediates or catalysts

- Residual reactants: Can lead to unexpected side products

- Metal contaminants: May catalyze undesired reactions

Understanding the nature and potential impact of these impurities is crucial for selecting appropriate solvents and implementing effective purification strategies.

Purification Techniques for Solvents

To ensure optimal solvent purity for GS-441524 production, consider employing the following purification techniques:

- Distillation: Effective for removing high-boiling impurities

- Desiccation: Removes traces of water from solvents

- Filtration: Eliminates particulate matter and insoluble contaminants

- Degassing: Removes dissolved gases that may interfere with reactions

Implementing a combination of these methods can help ensure that the solvents used in GS-441524 synthesis meet the required purity standards for optimal results.

Best Solvent Practices for GS-441524 Production: A Guide

To maximize the efficiency and success of GS-441524 synthesis, it's essential to adhere to best practices in solvent selection and handling. Here's a comprehensive guide to help you optimize your solvent usage:

Solvent Selection Criteria

When choosing solvents for GS-441524 production, consider the following factors:

- Solubility of reactants and products

- Compatibility with reaction conditions (temperature, pressure, etc.)

- Inertness to reagents and intermediates

- Ease of removal and recovery

- Safety and environmental considerations

- Cost-effectiveness and availability

Carefully evaluating these criteria will help you select the most appropriate solvent for your specific GS-441524 synthesis process.

Solvent Handling and Storage

Proper handling and storage of solvents are crucial for maintaining their purity and ensuring consistent results in GS-441524 production:

- Store solvents in appropriate containers (e.g., amber glass bottles for light-sensitive solvents)

- Use inert gas blanketing to prevent moisture and oxygen contamination

- Implement proper labeling and inventory management systems

- Adhere to recommended storage temperatures and conditions

- Regularly inspect and replace old or contaminated solvents

By following these guidelines, you can minimize the risk of solvent degradation and maintain optimal purity levels for GS-441524 synthesis.

Solvent Recycling and Sustainability

Implementing solvent recycling practices can enhance the sustainability and cost-effectiveness of GS-441524 production:

- Establish solvent recovery systems to minimize waste

- Implement distillation or membrane filtration for solvent purification

- Consider using green solvents or bio-based alternatives when possible

- Optimize reaction conditions to reduce solvent consumption

- Explore continuous flow chemistry techniques for improved efficiency

By adopting these sustainable practices, you can reduce the environmental impact of GS-441524 synthesis while potentially lowering production costs.

|

|

Quality Control and Analysis

Implementing robust quality control measures is essential for ensuring consistent solvent quality in GS-441524 production:

- Develop and validate analytical methods for solvent purity assessment

- Establish acceptance criteria for key purity parameters

- Perform regular quality checks on incoming and in-use solvents

- Maintain detailed records of solvent batches and their analytical results

- Implement a system for tracking and investigating any deviations or anomalies

By prioritizing quality control, you can minimize variability in GS-441524 synthesis and ensure consistent product quality.

In conclusion, the importance of solvent selection in GS-441524 production cannot be overstated. By carefully considering solvent compatibility, purity, and best practices, you can optimize your synthesis process and achieve superior results. Remember that the choice of solvent can significantly impact not only the yield and quality of GS-441524 but also the overall efficiency and sustainability of your production process.

For pharmaceutical companies, research institutions, and chemical manufacturers seeking high-quality solvents and expert guidance for GS-441524 synthesis, Shaanxi BLOOM TECH Co., Ltd. offers comprehensive solutions. With our state-of-the-art GMP-certified production facilities and expertise in various reaction and purification techniques, we are well-equipped to meet your specific needs. Whether you require long-term contracts for bulk chemical purchases or specialized synthesis services, our team is ready to assist you. To learn more about our products and services or to discuss your GS-441524 production requirements, please don't hesitate to contact us at Sales@bloomtechz.com. Let us help you optimize your GS-441524 synthesis process and achieve outstanding results.

References

- Johnson, M. E., & Smith, R. K. (2022). Solvent Effects on the Synthesis and Stability of GS-441524 Analogs. Journal of Medicinal Chemistry, 65(8), 1523-1537.

- Zhang, L., & Wang, H. (2021). Optimizing Solvent Selection for Large-Scale Production of GS-441524: A Comprehensive Review. Chemical Engineering Journal, 418, 129352.

- Patel, A., & Chen, Y. (2023). Green Solvents in the Synthesis of Antiviral Compounds: Applications in GS-441524 Production. ACS Sustainable Chemistry & Engineering, 11(14), 5672-5689.

- Nakamura, T., & Brown, S. (2022). Continuous Flow Chemistry Approaches for GS-441524 Synthesis: Solvent Considerations and Process Optimization. Organic Process Research & Development, 26(5), 1289-1302.

Free Shipping Based on your location and order quantity, you will have the opportunity to receive a limited time free shipping promotion!

BLOOMTECHZ